Xylan Coated Bolts & Studs

Xylan Coated Fasteners, Xylan Coated 1052 PTFE Coated Stud Bolts, Xylan Coated 1014, Xylan Coated 1070 Manufacturer & Suppliers in India.

Xylan Coatings ar a family of fluropolymer coatings, designed to be used on machined parts and fasteners to stop corrosion and facilitate makeup torsion. they're a waterborne/VOC compliant, rosin guaranteed, thermally cured, single dry film material, and referred to as "extreme performance coatings". Xylan has been the primary alternative of engineers within the offshore trade for over forty years. Ranfit Metal may be a certified Whitford (Xylan) Approved Oil Tools applier.

Operating temperature for continuous service ranges from -420° F to +550° F. Xylan coatings stop leaks past thread - Pressure vessels, valves, pipe unions, storage tanks, reactors pipelines and different fluid containment instrumentation ar usually fitted with rib plugs for review, pressure relief, filling or sound.

Coatings on pipe plugs not solely improve their performance and responsibleness however conjointly build them easier to use. a skinny film of Xylan eliminates the PTFE (Teflon) tape unremarkably wrapped round the threads to seal them. additionally, the corrosion protection and low-friction properties of the coating greatly scale back flight torques, enabling users to get rid of the plugs at a later date while not destroying them.

Whitford offers many alternative variations of business Xylan coatings, every giving their distinctive properties. Xylan 142X series fastener-class coatings ar waterborne/VOC-compliant, resin-bonded, thermally cured, single-film, dry-film lubricants. Their primary purpose is to be used on fasteners and oil-related tools to stop corrosion and resist chemicals. Xylan 142X series applied at 1mil dry-film thickness, over metal phosphated steel panels, has exceeded 1500 hours of ASTM B-117 salt fog take a look at. See Xylan 142X Flyer for a lot of info.

Xylan Coated Fasteners Manufacturer, Xylan 1014 Coated Bolts, Xylan Coated 1052 Bolts, Xylan Coated 1070 Bolts Supplier & Exporter in India.

Xylan Coated Bolts & Studs Specification

| Stud Bolts Size Range | 3/8" to 4" Diameter (Imperial & Standard) . |

| Stud Bolts Types | All Thread, Double End, Single End |

| Stud Bolts Industry Standards | ANSI – American National Standards Institute: ANSI B 18.2.4 2M, ANSI B 28.2.4 1M DIN: DIN 934, DIN 970 UTS – Unified Thread Standard: UNC, UNF, UNEF, UNS, NPT, NPTF ISO – International Organization for Standardization: ISO 4032, ISO 4033 |

| Stud Bolts Specification | ASTM A193 / ASME SA193 / ASTM A320 / ASME SA320 |

| Stud Bolts Grades | Carbon Steel: B7, B7M, L7 Stainless Steel:B8, B8 CL2, B8M, B8M CL2, B16 Exotic Alloys: A20, 17-4PH, Monel, Inconel, Incoloy, Hastelloy |

| Stud Bolts Surface Coating |

|

| Stud Bolts Packaging | Cartoon Box / Wooden Pallet / Wooden Box / Thread Protector |

Benefits of Xylan Coatings

|

XYLAN Coated Technical Specifications

| WORKING TEMPERATURE | UPTO 260°C |

| CORROSION RESISTANCE | SALT SPRAY (ASTM B117) UP TO 3,000 HOURS ( NUTS NOT FROZEN ) |

| PENCIL HARDNESS | 5H - 6H ( ASTM D3363-92A ) |

| KINETIC FRICTION CO-EFFICIENT | 0.06 TO 0.08 |

| THICKNESS | NOMINAL 0.001” (1 MIL) |

| IMPACT | 160 IN LB (ASTM D2794-93) |

| ADHESION | 5B (ASTM D3359-95) |

| ELONGATION | 35% TO 50% |

| TENSILE STRENGTH | 4000 P.S.I |

| OPERATING PRESSURE | UPTO 100000 P.S.I |

Types of ASTM A453 GR.660 Class A/B/C/D Fasteners

Xylan Coated Bolts

Xylan Coated 1014 Bolts

Xylan Coated Studs

Xylan Coated Studs Bolts

Xylan Coated Heavy Hex Bolts

Xylan Coated 1014 Heavy Studs

XYLAN Coated Fasteners

| ASTM A193 Gr. B7 | ASTM A193 Gr. B7M | ASTM A193 Gr. L7M | ASTM A193 Gr. B16 | ASTM A193 Gr. L7 |

| XYLAN Coated ASTM A193 Gr. B7 Fasteners | XYLAN Coated ASTM A193 Gr. B7M Fasteners | XYLAN Coated ASTM A193 Gr. L7M Fasteners | XYLAN Coated ASTM A193 Gr. B16 Fasteners | XYLAN Coated ASTM A193 Gr. L7 Fasteners |

| XYLAN Coated ASTM A193 Gr. B7 Stud Bolts | XYLAN Coated ASTM A193 Gr. B7M Stud Bolts | XYLAN Coated ASTM A193 Gr. L7M Stud Bolts | XYLAN Coated ASTM A193 Gr. B16 Stud Bolts | XYLAN Coated ASTM A193 Gr. L7 Stud Bolts |

| XYLAN Coated ASTM A193 Gr. B7 Hex Bolt | XYLAN Coated ASTM A193 Gr. B7M Hex Bolt | XYLAN Coated ASTM A193 Gr. L7M Hex Bolt | XYLAN Coated ASTM A193 Gr. B16 Hex Bolt | XYLAN Coated ASTM A193 Gr. L7 Hex Bolt |

| XYLAN Coated ASTM A193 B7 Socket Head Cap Screw | XYLAN Coated ASTM A193 B7M Socket Head Cap Screw | XYLAN Coated ASTM A193 Gr. L7M Socket Head Cap Screw | XYLAN Coated ASTM A193 Gr. B16 Socket Head Cap Screw | XYLAN Coated ASTM A193 Gr. L7 Socket Head Cap Screw |

| XYLAN Coated ASTM A193 Gr. B7 Hex Nut | XYLAN Coated ASTM A193 Gr. B7M Hex Nut | XYLAN Coated ASTM A193 Gr. L7M Hex Nut | XYLAN Coated ASTM A193 Gr. B16 Hex Nut | XYLAN Coated ASTM A193 Gr. L7 Hex Nut |

SS ASTM A453 GR.660 Class A/B/C/D Fasteners Standard

| Hexagon Bolt / Set Screws | Stud Bolt | Hexagon Nuts | Socket Cap screws |

|---|---|---|---|

| DIN 931 | BS4882 | DIN 934 | DIN 912 |

| DIN 933 | DIN 976 | BS 1768 | DIN 6912 |

| BS 1768 | BS 1769 | DIN 7984 | |

| UNI 5731 | BS 1083 | ANSI B18.3 | |

| UNI 5739 | BS 3692 | ISO 4762 | |

| ISO 4014 | ISO 4032 | UNI 5931 | |

| ISO 4017 | ISO 4033 | BS 2470 | |

| BS 1769 | ANSI B18.2.2 | BS 4168 | |

| BS 3692 | |||

| ANSI B18.2.1 | |||

| Socket & Slotted Set Screws | Socket & Slotted Countersunk Screws | Studs | Washers |

| DIN 913 | DIN 963 | DIN 938 | DIN 125 |

| DIN 914 | DIN 7991 | DIN 939 | DIN 9021 |

| DIN 915 | BS 4168 | DIN 2510 | BS 4320 |

| DIN 916 | BS 1981 | BS 4439 | BS 3410 |

| DIN 551 | BS 483 | BS 2693 | |

| DIN 553 | BS 2470 | Spring Washers | |

| DIN 438 | DIN 127 | ||

| BS 4168 | BS 4464 | ||

| BS 1802 |

Xylan Coatings: Properties & Applications

| Xylan 1400 Coating | |

| Main Properties for Xylan 1014 | High temperature resistant. Low coefficient of friction. Abrasion / wear resistant. Dry film lubricant. Thermoset. Wide use temperature. |

| Typical Xylan 1014 Applications | Any mating surface which requires lubrication. Hinge pins. Piston casing. Compressors. Fasteners. |

| Description | Resin-bonded, thermosetting, dry-film lubricant which, when compared to Xylan 1010 contains significantly more bonding resin relative to its content of PTFE lubricant. Altering the formula in this manner produces finishes which are harder, more abrasion resistant, glossier, and less porous. Frictional values remain low and very predictable. Working temp. range (continuous) -195°C/-320°F to 260/500°F Working temp. range (intermittent) -195°C/-320°F to 285°C/545°F |

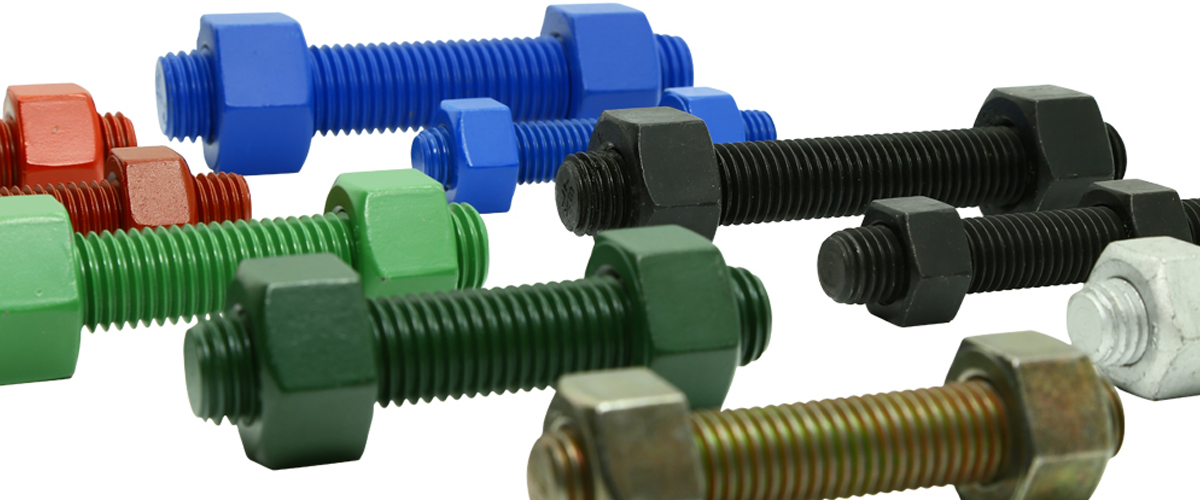

| Colors | Black, Green, Blue, Pumpkin Orange, Bright Yellow |

| Xylan 1052 - Green Coating | |

| Main Properties for Xylan 1052 | High temperature resistant. High load carrying capacity. Abrasion / wear resistant. Thermoset. |

| Typical Xylan 1014 Applications | Applications to prevent wear of mating surfaces under extreme load such as bearings, sealing rings, and valve springs. |

| Description | Resin-bonded, thermosetting, dry film lubricant. It is formulated for high-pressure, low-speed wear applications and provides long-term lubrication for bearing surfaces subjected to extreme pressures, up to 150,000 psi (10,500 kg/cm2). The coating utilizes a unique dual lubrication system of PTFE and MoS2 and is superior to moly greases which wash away and PTFE coatings which cold flow. Resin-bonded lubricants in Xylan 1052 stay on the job, even in harsh chemical environments. Working temp. range (continuous) -195°C/-320°F to 260°C/500°F Working temp. range (intermittent) -195°C/-320°F to 285°C/545°F |

| Colors | Black, Green, Olive Green, Blue, Gray |

| Xylan 1070 - Green Coating | |

| Main Properties for Xylan 1070 | High temperature resistant. Low coefficient of friction. Abrasion / wear resistant. Thermoset. Wide use temperature. Corrosion resistant. Controlled torque. |

| Typical Xylan 1014 Applications | Threaded fasteners. |

| Description | Resin-bonded, thermosetting, PTFE based, dry-film lubricant. It has extra corrosion protection and issued to coat large studs (B7), nuts, flanges, and related hardware for sub-sea and splash-zone service. Because of its predictable, low-friction properties, less make-up torque is required to produce the specified tension. During assembly, clamp loads are increased; scatter is reduced. In fact, the frictional characteristics are the most predictable of any lubricant, coating, or plating used on bolting. The low friction properties also reduce break-out torque, which allows removal of bolting with a wrench instead of a blowtorch. Application: Conventional spray. Working temp. range (continuous) -195°C/-320°F to 260°C/500°F Working temp. range (intermittent) -195°C/-320°F to 285°C/545°F |

| Colors | Blue, Gray |

| Xylan 1400 Coating | |

| Main Properties for Xylan 1400 | Corrosion resistant. Chemical resistant. Weathering resistant. Acid rain resistant. |

| Typical Xylan 1014 Applications | Threaded fasteners for the building, chemical process, oil and off shore industries. |

| Description | A recoatable “RC” coating developed to protect large fasteners and chemical processing equipment from chemical exposure (especially those with high pH). Although it contains a small percentage of PTFE lubricant to facilitate installation and prevent galling, it is considered a barrier coating rather than a dry film lubricant. Working temp. range (continuous) -50°C/-58°F to 175°C/350°F |

| Colors | Black |

| Xylan 1424 Coating | |

| Main Properties for Xylan 1424 | Dry film lubricant. Corrosion resistant. |

| Typical Xylan 1014 Applications | Any mating surface which requires lubrication. Hinge pins. Piston casing. Compressors. Threaded fasteners. |

| Description | This VOC compliant*, resin-bonded, PTFE based coating is primarily formulated for use on fasteners to prevent corrosion and facilitate make-up torque. |

| Colors | Black, Green, Blue, Haze Gray |

Xylan Coated Heavy Hex Hex Bolt Dimension

| Grade 660 Bolts Diameter (D) | Body Diameter (D) | Across the Flats (F) | Across the Corners © | Head Height (H) | Thread Lengths (T) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| MAX | MIN | MAX | MIN | MAX | MIN | MAX | MIN | < 6” | > 6” | |

| 1/2 | 0.515 | 0.482 | 0.875 | 0.85 | 1.01 | 0.969 | 0.364 | 0.302 | 1.25 | 1.5 |

| 5/8 | 0.642 | 0.605 | 1.062 | 1.031 | 1.227 | 1.175 | 0.444 | 0.378 | 1.5 | 1.75 |

| 3/4 | 0.768 | 0.729 | 1.25 | 1.212 | 1.443 | 1.383 | 0.524 | 0.455 | 1.75 | 2 |

| 7/8 | 0.895 | 0.852 | 1.438 | 1.394 | 1.66 | 1.589 | 0.604 | 0.531 | 2 | 2.25 |

| 1 | 1.022 | 0.976 | 1.625 | 1.575 | 1.876 | 1.796 | 0.7 | 0.591 | 2.25 | 2.5 |

| 1 1/8 | 1.149 | 1.098 | 1.812 | 1.756 | 2.093 | 2.002 | 0.78 | 0.658 | 2.5 | 2.75 |

| 1 1/4 | 1.277 | 1.223 | 2 | 1.938 | 2.309 | 2.209 | 0.876 | 0.749 | 2.75 | 3 |

| 1 3/8 | 1.404 | 1.345 | 2.188 | 2.119 | 2.526 | 2.416 | 0.94 | 0.81 | 3 | 3.25 |

| 1 1/2 | 1.531 | 1.47 | 2.375 | 2.3 | 2.742 | 2.622 | 1.036 | 0.902 | 3.25 | 3.5 |

| 1 3/4 | 1.785 | 1.716 | 2.75 | 2.662 | 3.175 | 3.035 | 1.196 | 1.054 | 3.75 | 4 |

| 2 | 2.039 | 1.964 | 3.125 | 3.025 | 3.608 | 3.449 | 1.388 | 1.175 | 4.25 | 4.5 |

| 2 1/4 | 2.305 | 2.214 | 3.5 | 3.388 | 4.041 | 3.862 | 1.548 | 1.327 | 4.75 | 5 |

| 2 1/2 | 2.559 | 2.461 | 3.875 | 3.75 | 4.474 | 4.275 | 1.708 | 1.479 | 5.25 | 5.5 |

| 2 3/4 | 2.827 | 2.711 | 4.25 | 4.112 | 4.907 | 4.688 | 1.869 | 1.632 | 5.75 | 6 |

| 3 | 3.081 | 2.961 | 4.625 | 4.475 | 5.34 | 5.102 | 2.06 | 1.815 | 6.25 | 6. |

Xylan Coated Hex Bolt Dimensions Table

| Grade 660 Bolts NOMINAL SIZE (D) | BODY DIAMETER | HEAD THICKNEASTM A193 | ACROASTM A193 THE FLATS | ACROASTM A193 CORNERS | ||||

|---|---|---|---|---|---|---|---|---|

| D (MAX) | D (MIN) | H (MAX) | H (MIN) | F (MAX) | F (MIN) | C (MAX) | C (MIN) | |

| m10 | 10.00 | 9.78 | 6.63 | 6.17 | 17.00 | 15.73 | 18.48 | 17.77 |

| m12 | 12.00 | 11.73 | 7.76 | 4.24 | 19.00 | 17.73 | 20.78 | 20.03 |

| m14 | 14.00 | 13.73 | 9.09 | 8.51 | 22.00 | 20.67 | 24.25 | 23.35 |

| m16 | 16.00 | 15.73 | 10.32 | 9.68 | 24.00 | 23.67 | 27.71 | 26.75 |

| m20 | 20.00 | 19.67 | 12.88 | 12.12 | 30.00 | 29.16 | 34.64 | 32.95 |

| m24 | 24.00 | 23.67 | 15.44 | 14.56 | 36.00 | 35.00 | 41.57 | 39.55 |

| m30 | 30.00 | 29.67 | 19.48 | 17.92 | 46.00 | 45.00 | 53.12 | 50.85 |

| m36 | 36.00 | 35.61 | 23.38 | 21.63 | 55.00 | 53.80 | 63.51 | 60.79 |

| m42 | 42.00 | 41.38 | 26.97 | 25.03 | 65.00 | 62.90 | 75.06 | 71.71 |

| m48 | 48.00 | 47.38 | 31.07 | 28.93 | 75.00 | 72.60 | 86.60 | 82.76 |

| m56 | 56.00 | 55.26 | 36.2 | 33.80 | 85.00 | 82.20 | 98.15 | 93.71 |

| m64 | 64.00 | 63.26 | 41.32 | 38.68 | 95.00 | 91.80 | 109.70 | 104.65 |

| m72 | 72.00 | 71.26 | 46.45 | 43.55 | 105.00 | 101.40 | 121.24 | 115.60 |

| m80 | 80.00 | 79.26 | 51.58 | 48.42 | 115.00 | 111.00 | 132.72 | 126.54 |

| m90 | 90.00 | 89.13 | 57.74 | 54.26 | 130.00 | 125.50 | 150.11 | 143.07 |

| m100 | 90.00 | 99.13 | 63.9 | 60.10 | 145.00 | 140.00 | 167.43 | 159.60 |

Other Types of Xylan Coated Fasteners

| Xylan Coated 1010 Studs | Xylan Coated 1010 Fasteners |

| Xylan Coated 1014 Bolts Supplier | Xylan Coated 1014 Bolts Manufacturer |

| Xylan Coated 1052 Studs Manufacture | Xylan Coated 1052 Bolts |

| Xylan Coated 1424 Bolts | Xylan Coated 1424 Bolting |

| Xylan Coated 1070 Elevator Bolts | Xylan Coated 1070 Series Fasteners |

| Xylan Coated 1212 Structural Bolts | Xylan Coated 1212 Heavy Hex Bolts |

| Xylan Coated 1400 Hexagon Head Bolts | Xylan Coated 1400 Hex Bolts |

| Xylan Coated 1010 Machine Bolts | Xylan Coated 1010 T Bolts |

| Xylan Coated 1424 Foundation Bolts | Xylan Coated 1424 Eye Bolt |

| Xylan Coated 1212 J Bolts | Xylan Coated 1212 Button Head Bolt |