DIN 2510 Type G, H, P, Q, R & S Part 4 Stud Dimensions

For Use With Bolts With Reduced Shank.

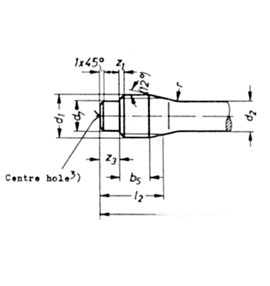

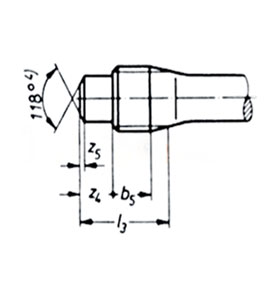

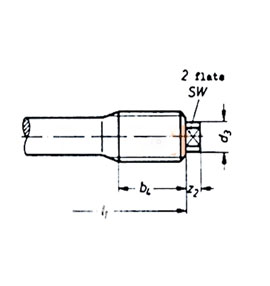

Din 2510 Studs With Reduced Shank Metal End

DIN 2510 Part 4 Type G Studs With Flat Bearing Face

DIN 2510 Part 4 Type H Studs With Coned Bearing Face

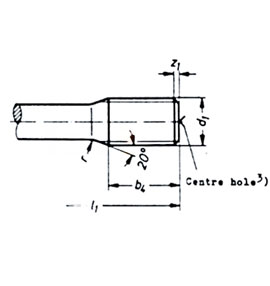

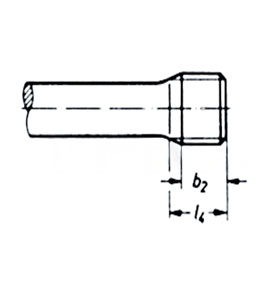

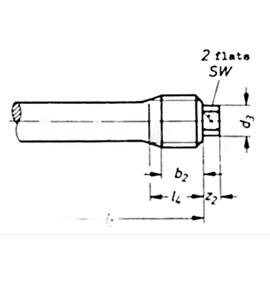

Din 2510 Studs With Reduced Shank Nut End

DIN 2510 Part 4 Type P Studs With Long Thread

DIN 2510 Part 4 Type Q Studs With Short Thread

DIN 2510 Part 4 Type R Studs With Long Thread And Point

DIN 2510 Part 4 Type S Studs With Short Thread And Point

DIN 2510 Type L, K, KU, Z, ZU Part 3 Stud Dimensions

| d1 thread size | d2 | d3 | d7 | b2 | b4 | b5 | z2 | z3 | z4 | width accross flats |

|---|---|---|---|---|---|---|---|---|---|---|

| M 12 | 8.5 | 8 | 8.5 | 13 | 23 | 10 | 4 | 4.5 | 6 | 7 |

| M 16 | 12 | 12 | 12 | 16 | 27 | 13.5 | 5 | 5 | 7 | 10 |

| M 20 | 15 | 14 | 15 | 20 | 33 | 16.5 | 6 | 7 | 9.5 | 11 |

| M 24 | 18 | 14 | 18 | 24 | 38 | 20 | 6 | 8 | 11 | 11 |

| M 27 | 20.5 | 18 | 21 | 27 | 43 | 22.5 | 6 | 8 | 11 | 13 |

| M 30 | 23 | 18 | 23 | 30 | 46 | 25 | 6 | 9.5 | 13 | 13 |

| M 33 | 25.5 | 25 | 26 | 33 | 51 | 27.5 | 9 | 9.5 | 13 | 22 |

| M 36 | 27.5 | 25 | 28 | 36 | 54 | 30 | 9 | 10.5 | 14.5 | 22 |

| M 39 | 30.5 | 28 | 31 | 39 | 57 | 32.5 | 10 | 10.5 | 14.5 | 24 |

| M 42 | 32.5 | 28 | 33 | 42 | 61 | 35 | 10 | 12 | 17 | 24 |

| M 45 | 35.5 | 32 | 36 | 45 | 64 | 37.5 | 11 | 12 | 17 | 27 |

| M 48 | 37.5 | 32 | 38 | 48 | 67 | 39.5 | 11 | 13 | 18.5 | 27 |

| M 52 | 41 | 36 | 42 | 52 | 72 | 43.5 | 12 | 13 | 18.5 | 30 |

| M 56 | 44 | 40 | 45 | 56 | 77 | 46.5 | 13 | 14.5 | 20.5 | 32 |

| M 64 | 51 | 42 | 52 | 64 | 88 | 53.5 | 14 | 15.5 | 19 | 36 |

| M 72x6 | 58.5 | 50 | 60 | 72 | 96 | 60.5 | 15 | 15.5 | 19 | 41 |

| M 80x6 | 666 | 50 | 68 | 80 | 104 | 67.5 | 15 | 15.5 | 19.5 | 41 |

| M 90x6 | 75 | 50 | 78 | 90 | 115 | 76.5 | 15 | 15.5 | 20 | 41 |

| M 100x6 | 84 | 50 | 88 | 100 | 125 | 85.5 | 15 | 15.5 | 20.5 | 41 |

| M 110x6 | 92.5 | 50 | 98 | 110 | 136 | 94.5 | 15 | 15.5 | 20.5 | 41 |

| M 120x6 | 102 | 50 | 108 | 120 | 147 | 10.3.5 | 15 | 15.5 | 21 | 41 |

DIN 2510 Designation of Type GP STUDS with Threads

| Product | Type | Size | Dimensional Specification | Grade |

|---|---|---|---|---|

| Stud | GP | M56 X150 | DIN 2510 | X6NiCrTiMoVB25-15-2 |

DIN 2510 Technical Delivery Conditions

- DIN 2510-Type G & H metal ends are combined with Type P, Q, R, S suitable to match various DIN 2510 Type NF & TF nuts along with Type D & E Extension Sleeves. The Below list resembles various combinations manufactured in DIN 2510 Studs.

- DIN 2510 Form GP

- DIN 2510 Form GQ

- DIN 2510 Form GR

- DIN 2510 Form GS

- DIN 2510 Form HP

- DIN 2510 Form HQ

- DIN 2510 Form HR

- DIN 2510 Form HS

- All Material Specifications are accordance with DIN 267 Part 13 or EN 10269, though these studs can be manufactured in respective ASTM/ ASME specifications on request.

- Marking: All Studs to be marked in accordance with DIN 267 Part 13

Special Note: The Marking should be applied on end face of the point z2 or to the end face at the nut end. - Type: Incase if required type "f" should be according to DIN 267

- The designation for type "m" shall read as Stud GR M56 DIN 2510 –f- X6NiCrTiMoVB25-15-2 Instead of the code number, the code letter of the material can also be stated in the designation. IN such case the designation shall read as Stud GS M56 DIN 2510 – G

- Nominal Length "l1" to be clearly stated in the purchase order while ordering.

- For DIN 2510 Stud size M64 & above the angle is 150 Degrees

- If DIN 2510 Studs size M64 & above are required without hole d4, the letter " o" should be inserted in the designation which will read as STUD GR0 M64X400 DIN 2510 – 24CrMo5

- Centering according to DIN 332 & Detail Y only for Studs of Type "f"

- Refer Below Image for more Details.

DIN 2510 Materials

Heat Treated Steels

| Werkstoff Number | Name | Mark |

|---|---|---|

| 1.0501 | C 35 | Y |

| 1.0503 | C 45 | - |

| 1.0540 | C 50 | - |

| 1.0601 | C 60 | - |

| 1.1151 | C22E (Ck 22) | - |

| 1.1181 | C35E (Ck 35) | Yk |

| 1.1191 | C45E (Ck 45) | - |

| 1.1221 | C22E (Ck 22) | - |

| 1.6511 | 36CrNiMo4 | - |

| 1.6580 | 30CrNiMo8 | - |

| 1.6582 | 34CrNiMo6 | - |

| 1.7033 | 34Cr4 | - |

| 1.7035 | 41Cr4 | - |

| 1.7218 | 25CrMo4 | - |

| 1.7220 | 34CrMo4 | - |

| 1.7225 | 42CrMo4 | - |

| 1.7227 | 42CrMoS4 | - |

| 1.7228 | 50CrMo4 | - |

Low temperature Steels

| Werkstoff | Short name | Character(Symbol) | AD-2000 | Specification | Equivalent | |

|---|---|---|---|---|---|---|

| -40 °C | 1.6582 | 34CrNiMo6 | - | - | DIN EN 10269 | - |

| - | 1.6580 | 30CrNiMo8 | - | - | DIN EN 10269 | - |

| - | - | - | - | - | - | - |

| -60°C | 1.7218 | 25CrMo4 | KG | W10 | DIN EN 10269 | ∼SAE 4130 |

| - | 1.7258 | 24CrMo5 | G | - | zurückgezogen | - |

| - | 1.7219 | 26CrMo4 | KA | - | zurückgezogen | - |

| - | - | - | - | - | - | - |

| -100°C | 1.7225 | 42CrMo4 | GC | - | DIN EN 10269 | ∼ASTM A320 L7 |

| - | - | - | - | - | - | - |

| -120°C | 1.5680 | X12Ni5 | KB | W10 | DIN EN 10269 | ∼SAE 2515 |

| - | - | - | - | - | - | - |

| -196°C | 1.4301 | X5CrNi18-10 | A2 | W10 | DIN EN 10269 | ∼AISI 304 |

| - | 1.4307 | X2CrNi18-9 | A2 | W10 | DIN EN 10269 | ∼AISI 304 L |

| - | 1.4401 | X5CrNiMo17-12-2 | A4 | W10 | DIN EN 10269 | ∼AISI 316 |

| - | 1.4404 | X2CrNiMo17-12-2 | A4 | W10 | DIN EN 10269 | ∼AISI 316 L |

| - | 1.4980 | X6NiCrTiMoVB25-15-2 | SD | - | DIN EN 10269 | ∼AISI 660 |

| - | 2.4952 | NiCr20TiAl | SB | - | DIN EN 10269 | ∼Alloy 80A |

| - | 2.4669 | NiCr15Fe7TiAl | - | - | DIN EN 10269 | ∼Alloy X-750 |

| - | - | - | - | - | - | - |

| -270°C | 1.4429 | X2CrNiMoN17-13-3 | - | W10 | DIN EN 10269 | ∼AISI 316 LN |

| - | 1.4910 | X3CrNiMoBN17-13-3 | - | W10 | DIN EN 10269 | - |

Heat resistant steels

| Werkstoff | Short name | Character(Symbol) | AD-2000 | Specification | Equivalent | |

|---|---|---|---|---|---|---|

| 600°C | 1.4913 | X19CrMoNbVN11-1 | VW | - | DIN EN 10269 | - |

| 1.7711 | 40CrMoV4-6 | GB | - | DIN EN 10269 | - | |

| 500°C | 1.4923 | X22CrMoV12-1 | V / VH | W7 | DIN EN 10269 | - |

| 1.7225 | 42CrMo4 | GC | W7 | DIN EN 10269 | ∼ASTM A193 B7 | |

| 1.7709 | 21CrMoV5-7 | GA | W7 | DIN EN 10269 | - | |

| 400°C | 1.4404 | X2CrNiMo17-12-2 | A4 | W2 | DIN EN 10269 | ∼AISI 316 L |

| 1.4429 | X2CrNiMoN17-13-3 | - | W2 | DIN EN 10269 | ∼AISI 316 LN | |

| 1.4571 | X6CrNiMoTi17-12-2 | A5 | W2 | DIN EN 10088-3 | ∼AISI 316 Ti | |

| 1.4541 | X6CrNiTi18-10 | - | W2 | DIN EN 10088-3 | ∼AISI 321 | |

| 1.4539 | X1NiCrMoCuN25-20-5 | - | W2 | DIN EN 10088-3 | ∼AISI 904 L | |

| 1.7218 | 25CrMo4 | KG | W7 | DIN EN 10269 | ∼SAE 4130 | |

| 1.7258 | 24CrMo5 | G | - | zurückgezogen | - | |

| 1.7219 | 26CrMo4 | KA | - | zurückgezogen | - | |

| 1.5511 | 35B2 | YB | W7 | DIN EN 10269 | - | |

| 1.1181 | C35E | YK | W7 | DIN EN 10269 | - | |

| 350°C | 1.4548 | X5CrNi CuNb17-4-4 | - | - | WL 1.4548 Teil 2 | ∼AISI 630 / 17-4 PH |

| 1.4542 | X5CrNiCuNb16-4 | - | - | DIN EN 10088-3 | ∼AISI 630 / 17-4 PH | |

| 1.1191 | C45E | - | - | DIN EN 10269 | - | |

| 300°C | 1.4401 | X5CrNiMo17-12-2 | A4 | W2 | DIN EN 10269 | ∼AISI 316 |

| 1.4301 | X5CrNi18-10 | A2 | W2 | DIN EN 10269 | ∼AISI 304 |

High temperature steels

| Werkstoff Number | Short name | Mark/ Brand Name |

|---|---|---|

| 1.4910 | X3CrNiMoN1713 | |

| 1.4913 | X19CrMoVNbN11-1 | VW |

| 1.4923 | X22CrMoV12 1 | V |

| 1.4948 | X6CrNi1811 | Avesta 18-8 |

| 1.4958 | X5NiCrAlTi31-20 | Incoloy 800 H |

| 1.4959 | X8NiCrAlTi32-21 | Incoloy 800 HT |

| 1.4961 | X8CrNiNb1613 | K |

| 1.4980 | X5NiCrTi2615 | SD |

| 1.4981 | X8CrNiMoNb1616 | O |

| 1.4986 | X8CrNiMoBNb1616 | S |

| 2.4952 | NiCr20TiAl | Nimonic 80A |

| 2.4669 | NiCr15Fe7TiAl | Inconel X-750 |

| 2.4633 | NiCr25FeAlY | Alloy 602 CA |

| (Nicrofer 6025 HT) | ||

| 2.4663 | NiCr23Co12Mo | Inconel 617 |

| 2.4668 | NiCr19NbMo | Inconel 718 |

| 2.4665 | NiCr19NbMo | Hastelloy X |

Non Magnetic Steels

| Werkstoff Number | Short name | Brand Name |

|---|---|---|

| 1.3948 | X4CrNiMnMoN 19 13 8 | |

| 1.3952 | X2CrNiMoN 18 14 | |

| 1.3957 | X2CrNiMoNbN 21 15 | |

| 1.3964 | X2CrNiMnMoNNb21 16 5 3 | |

| 1.3974 | X3CrNiMoNbN 23 17 |

Heat resistant steels and nickel alloys

| Werkstoff Number | Short name | Brand Name |

|---|---|---|

| 1.4713 | X10CrAlSi7 | SICRO 8 |

| 1.4724 | X10CrAlSi13 | SICRO 9 |

| 1.4742 | X10CrAlSi18 | SICRO 10 |

| 1.4762 | X10CrAlSi25 | SICRO 12 |

| 1.4821 | X15CrNiSi25-4 | |

| 1.4828 | X15CrNiSi20-12 | AISI 309 |

| 1.4835 | X9CrNiSiNCe21-11-2 | 253 MA |

| 1.4841 | X15CrNiSi2521 | AISI 314 (310) |

| 1.4845 | X8CrNi25-21 | AISI 310S |

| 1.4864 | X12NiCrSi35-16 | AISI 330 |

| 1.4876 | X10NiCrAlTi32-21 | Incoloy 800 |

| 1.4876 H | X10NiCrAlTi3220 | Incoloy 800 H |

| 1.4876 HT | X8NiCrAlTi3221 | Incoloy 800 HT |

| 1.4878 | X8CrNiTi18-10 | |

| 2.4816 | NiCr15Fe | Inconel 600 |

| 2.4851 | NiCr23Fe | Inconel 601 |

| 2.4856 | NiCr22Mo9Nb | Inconel 625 |

| 2.4951 | NiCr20Ti | Nimonic 75 |

Rust & Acid Resistant Materials

| Werkstoff Number | Short name | Mark/Brand Name |

|---|---|---|

| 1.4006 | X12Cr13 | |

| 1.4016 | X6Cr17 | |

| 1.4021 | X20Cr13 | AISI 420 |

| 1.4024 | X15Cr13 | |

| 1.4028 | X30Cr13 | |

| 1.4034 | X46Cr13 | |

| 1.4057 | X17CrNi16-2 | AISI 431 |

| 1.4104 | X14CrMoS17 | AISI 430F |

| 1.4112 | X90CrMoV18 | |

| 1.4122 | X35CrMo17-1 | |

| 1.4301 | X5CrNi18-10 | AISI 304 |

| 1.4305 | X8CrNiS18-9 | AISI 303 |

| 1.4306 | X2CrNi19-11 | AISI 304L |

| 1.4310 | X10CrNi18-8 | |

| 1.4313 | X3CrNiMo13-4 | |

| 1.4361 | X1CrNiSi18-15-4 | |

| 1.4362 | X2CrNiN23-4 | SAF 2304 |

| 1.4371 | X2CrMnNiN17-7-5 | |

| 1.4401 | X5CrNiMo17-12-2 | AISI 316 |

| 1.4404 | X2CrNiMo17-12-2 | AISI 316L |

| 1.4410 | X2CrNiMoN25-7-4 | SAF 2507 |

| 1.4418 | X4CrNiMo16-5-1 | |

| 1.4429 | X2CrNiMoN17-13-3 | AISI 316LN |

| 1.4435 | X2CrNiMo18-14-3 | AISI 316L |

| 1.4436 | X3CrNiMo17-13-3 | AISI 316 |

| 1.4438 | X2CrNiMo18-15-4 | AISI 317L |

| 1.4439 | X2CrNiMoN17-13-5 | AISI 317LNM |

| 1.4460 | X3CrNiMoN27-5-2 | AISI 329 |

| 1.4462 | X2CrNiMoN22-5-3 | SAF 2507 |

| 1.4501 | X2CrNiMoCuWN25-7-4 | Zeron 100 |

| 1.4507 | X2CrNiMoCuN25-7-4 | |

| 1.4529 | X1NiCrMoCuN25-20-7 | Alloy 926 |

| 1.4539 | X1NiCrMoCu25-20-5 | Uranus B6 |

| 1.4541 | X6CrNiTi18-10 | AISI 321 |

| 1.4542 | X5CrNiCuNb16-4 | 17-4PH |

| 1.4547 | X1CrNiMoCuN20-18-7 | 254SMO |

| 1.4550 | X6CrNiNb18-10 | AISI 347/348 |

| 1.4562 | X1NiCrMoCu32-28-7 | Alloy 31 |

| 1.4563 | X1NiCrMoCu31-27-4 | Sanicro 28 |

| 1.4571 | X6CrNiMoTi17-12-2 | AISI 316 Ti |

| 1.4578 | X3CrNiCuMo17-11-3-2 | |

| 1.4580 | X6CrNiMoNb17-12-2 | |

| 1.4586 | X5NiCrMoCuNb2218 |

Duplex and Super Duplex Steels

| Werkstoff Number | Short name | Brand Name |

|---|---|---|

| 1.4362 | X2CrNiN23-4 | SAF 2304 |

| 1.4410 | X2CrNiMoN25-7-4 | SAF 2507 |

| 1.4460 | X3CrNiMoN27-5-2 | AISI 329 |

| 1.4462 | X2CrNiMoN22-5-3 | SAF 2507 |

| 1.4501 | X2CrNiMoCuWN25-7-4 | (Zeron 100) |

High corrosion resistant nickel alloys

| Werkstoff Number | Short name | Brand Name |

|---|---|---|

| 2.4066 | Ni 99,2 | Nickel 200 |

| 2.4068 | LC-Ni 99 | Nickel 201 |

| 2.4360 | NiCu30Fe | Monel 400 |

| 2.4375 | NiCu30Al | MonelK 500 |

| 2.4600 | NiMo29Cr | Hastelloy B-3 |

| 2.4602 | NiCr21Mo14W | Hastelloy C-22 |

| 2.4603 | Hastelloy G-30 | |

| 2.4605 | NiCr23Mo16Al | Alloy 59 |

| 2.4606 | Inconel 686 | |

| 2.4610 | NiMo16Cr16Ti | Hastelloy C-4 |

| 2.4617 | NiMo28 | Hastelloy B-2 |

| 2.4619 | NiCr22Mo7Cu | Hastelloy G-3 |

| 2.4630 (2.4951) | NiCr20Ti | Nimonic 75 |

| 2.4631 (2.4952) | NiCr20TiAl | Nimonic 80A |

| 2.4632 (2.4969) | NiCr20Co18Ti | Nimonic 90 |

| 2.4633 | NiCr25FeAlY (Nicrofer6025 HT) | Alloy 602 CA |

| 2.4634 | NiCo20Cr15MoAlTi | Nimonic 105 |

| 2.4654 | NiCr19Co14Mo4Ti | Waspaloy |

| 2.4658 | NiCr7030 | Cronix70 |

| 2.466 | NiCr20CuMo | 20Cb3/Alloy 20 |

| 2.4663 | NiCr23Co12Mo | Inconel 617 |

| 2.4665 | NiCr19NbMo | Hastelloy X |

| 2.4668 | NiCr19NbMo | Inconel 718 |

| 2.4669 | NiCr15Fe7TiAl | Inconel X-750 |

| 2.4675 | NiCr23Mo16Cu | Hastelloy C-2000 |

| 2.4816 | NiCr15Fe | Inconel 600 |

| 2.4819 | NiMo16Cr15W | Hastelloy C-276 |

| 2.4851 | NiCr23Fe | Inconel 601 |

| 2.4856 | NiCr22Mo9Nb | Inconel 625 |

| 2.4858 | NiCr21Mo | Incoloy 825 |

| 2.4951 | NiCr20Ti | Nimonic 75 |

| 2.4952 | NiCr20TiAl | Nimonic 80A |

| 2.4969 | NiCr20Co18Ti | Nimonic 90 |

Titanium & Titanium Alloys

| Werkstoff Number | Short name | ASTM Werkstoff Number |

|---|---|---|

| 3.7035 | Titan | Titan Gr.2 |

| 3.7165 | TiAl6V4 | Titan Gr.5 |

| 3.7235 | Ti2Pd | Titan Gr.7 |

Special Metals

| Werkstoff Number | Brand Name | UNS Number |

|---|---|---|

| 1.4542 | 17-4PH | UNS S17400 |

| 1.4547 | 254 SMO | UNS S31254 |

| AerMet100 Alloy | UNS K92580 | |

| Ferralium 255 | ||

| 1.6772 | Monix 3 K | |

| 1.3964 | Nitronic50 | |

| Nitronic60 | UNS S21800 | |

| 1.4462 | SAF 2205 | UNS S31803 |

| 1.4362 | SAF 2304 | UNS S32304 |

| 1.441 | SAF 2507 | UNS S32750 |

| 1.4563 | SANICRO 28 | |

| Tantal | ||

| Uranus 50 | ||

| -1.4501 | Zeron 100 | UNS S32760 |

| Zirconium 702 | UNS R60702 | |

- Carbon Steel 1018, 1020, 1040, 1045

- Alloy Steel 4130, 4140, 4142, 4340, 6150, 8620

- Chrome Moly Steel 25CRMO4, 21CRMOV5-7, 42CRMO4, 42CRMOV4-6

- Austenitic Stainless Steel 301, 302, 303, 304, 316, 317, 321, 310, 309, 329, 347 & 348

- Martensitic / Ferritic Stainless Steel 403, 405, 409, 410, 414, 416, 418, 420 & 430F

- Super Austenitic Stainless Steel 904l, 253Ma, Alloy 20, Al-6xn, 310Moln, Alloy 230, Alloy 330 , Alloy 333

- Precipitation Hardening Stainless Steel Alloy A-286, A453 GRADE 660, 15-5 Ph, 15-7 Ph, 17-7 Ph

- Nitronic 30, 32, 33, 40

- Duplex 32205 (F60), 31803 (F51);Super Duplex 32750 ( F53) , 32760 (F55), 329, 255FG46

- Inconel 600, 601, 602, 603, 617, 625, 686, 702, 713, 718, 725, 738, 740, 783, X-750, 701, 901, 939

- Incoloy 800, 800H, 800HT, 825, 925, 926, 945

- Hastelloy C276, C22,C-2000,C4,B, B2, B3, G30, X, N

- Monel Alloy 400, K-500, R405

- Nimonic Alloy 80A, 90, 105, 115, 263

- Titanium Grade1, 2, 3, 4, 5, 6, 7,8, 9, 11, 12, 19,23

- Nickel 200, 201

- Copper Nickel 70/30, 90/10

- Silicon Bronze C651, C655, C656

- Cobalt Alloys Invar 36 / 42, Waspalloy, MP35N / 159, Stellite 3/6/12/21, Rene 41, L605

- Molybdenum Grade 361/363/364/365

- Durehete 900/950/1055, JETHETE X19/M152, Hiduron 130/190, Tantalum, Zircoloy, Aluminium Alloy 2024, 6061, 7075

ASTM / ASME Specification

| Grade Identification | Specification | Products | Material | Comparative EN Werkstoff |

|---|---|---|---|---|

| No Grade Mark | SAE J429 Grade 1 | Bolts, Screws, Studs |

Low or Medium Carbon Steel | --- |

| ASTM A307 Grade A & B | Low Carbon Steel | --- | ||

| SAE J429 Grade 2 | Low or Medium Carbon Steel | --- | ||

| No Grade Mark | SAE J429 Grade 4 | Studs | Medium Carbon Cold Drawn Steel |

--- |

| B5 | ASTM A193 Grade B5 | Bolts, Screws, Studs for High Temperature Service Class 1: Carbide solution treated |

AISI 501 | ~1.7362 |

| B6 | ASTM A193 Grade B6 | AISI 410 | ~1.4006 | |

| B7 | ASTM A193 Grade B7 | AISI 4140, 4142, 4105 | ~1.7225 | |

| B16 | ASTM A193 Grade B16 | CrMoVa Alloy Steel | ~1.7711 | |

| B8 | ASTM A193 Grade B8 Class 1 | AISI 304 | ~1.4301 | |

| B8C | ASTM A193 Grade B8C Class 1 | AISI 347 | ~1.4550 | |

| B8M | ASTM A193 Grade B8M Class 1 | AISI 316 | ~1.4401 | |

| B8T | ASTM A193 Grade B8T Class 1 | AISI 321 | ~1.4541 | |

| B8 | ASTM A193 Grade B8 Class 2 | Bolts, Screws, Studs for High Temperature Service Class 2: Carbide solution treated and strain hardend |

AISI 304 Strain Hardend | ~1.4301 |

| B8C | ASTM A193 Grade B8C Class 2 | AISI 347 Strain Hardend | ~1.4550 | |

| B8M | ASTM A193 Grade B8M Class 2 | AISI 316 Strain Hardend | ~1.4401 | |

| B8T | ASTM A193 Grade B8T Class 2 | AISI 321 Strain Hardend | ~1.4541 | |

| L7 | ASTM A320 Grade L7 | Bolts, Screws, Studs for Low Temperature Service Quenched and Tempered |

AISI 4140, 4142, 4145 | ~1.7225 |

| L7A | ASTM A320 Grade L7A | AISI 4037 | --- | |

| L7B | ASTM A320 Grade L7B | AISI 4137 | ~1.7220 | |

| L7C | ASTM A320 Grade L7C | AISI 8740 | ~1.6546 | |

| L43 | ASTM A320 Grade L43 | AISI 4340 | ~1.6580 | |

| B8 | ASTM A320 Grade B8 Class 1 | Bolts, Screws, Studs for Low Temperature Service Class 1: Carbide solution treated |

AISI 304 | ~1.4301 |

| B8C | ASTM A320 Grade B8 Class 1 | AISI 347 | ~1.4550 | |

| B8T | ASTM A320 Grade B8 Class 1 | AISI 321 | ~1.4541 | |

| B8F | ASTM A320 Grade B8 Class 1 | AISI 303 (Se) | ~1.4305 | |

| B8M | ASTM A320 Grade B8 Class 1 | AISI 316 | ~1.4401 | |

| B8 | ASTM A320 Grade B8 Class 1 | Bolts, Screws, Studs for Low Temperature Service Class 2: Carbide solution treated and strain hardend |

AISI 304 | ~1.4301 |

| B8C | ASTM A320 Grade B8C Class 2 | AISI 347 | ~1.4550 | |

| B8T | ASTM A320 Grade B8T Class 2 | AISI 321 | ~1.4541 | |

| B8F | ASTM A320 Grade B8F Class 2 | AISI 303 (Se) | ~1.4305 | |

| B8M | ASTM A320 Grade B8M Class 2 | AISI 316 | ~1.4401 | |

| 3 Radial Lines 120° | SAE J429 Grade 5 | Bolts, Screws, Studs | Medium Carbon Steel Quenched and Tempered |

--- |

| ASTM A449 | --- | |||

| 3 Radial Lines 90° | SAE J429 Grade 5.1 | Bolts, Screws, Studs | Low or Medium Carbon Steel Quenched and Tempered |

--- |

| 3 Radial Lines 60° | SAE J429 Grade 5.2 | Bolts, Screws, Studs | Low Carbon Martensitic Steel Quenched and Tempered |

--- |

| A325 | ASTM A325 Type 1 | High Strength Structural Bolts | Medium Carbon Steel Quenched and Tempered |

--- |

| -- | ASTM A325 Type 2 (Withdrawn) |

Low Carbon Martensitic Steel Quenched and Tempered |

--- | |

| A325 | ASTM A325 Type 3 | Atmospheric Corrosion Resisting Steel Quenched and Tempered |

--- | |

| BD | ASTM A354 Grade BD | Bolts, Studs | Alloy Steel Quenched and Tempered |

--- |

| BC | ASTM A354 Grade BC | --- | ||

| 5 Radial Lines | SAE J429 Grade 7 | Bolts, Screws | Medium Carbon Alloy Steel Quenched and Tempered |

--- |

| 6 Radial Lines 60° | SAE J429 Grade 8 | Bolts, Screws, Studs | Medium Carbon Alloy Steel Quenched and Tempered |

--- |

| No Grade Mark | SAE J429 Grade 8.1 | Studs | Medium Carbon Alloy or SAE 1041 Modified Elevated Temperature Drawn Steel | --- |

| A490 | ASTM A490 | High Strength Structural Bolts | Alloy Steel Quenched and Tempered | ~1.0050 |

| A453/A453M | ASTM A453/A453M Grade 660 | Class A / Class B / Class C / Class D | --- | --- |

| ASTM A453/A453M Grade 651 | Class A / Class B | --- | --- | |

| ASTM A453/A453M Grade 662 | Class A / Class B | --- | --- | |

| ASTM A453/A453M Grade 665 | Class A / Class B | --- | --- | |

| ASTM A453/A453M Grade 668 | Class A / Class B | --- | --- |